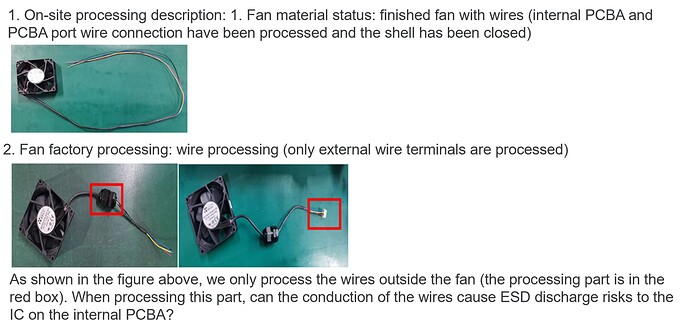

Dear expert (Johnk), hello: First of all, the incoming fan material is: finished fan with wires (internal PCBA and PCBA port wire connection have been processed and the shell is sealed). We only process the wire ends outside the fan (staff will not directly touch the PCBA). When the staff touch the bare wire ends of the wires, will the IC on the PCBA motherboard be damaged by electrostatic discharge through the wire conduction? How big is this risk?

I see two areas where there could be an ESD risk.

The first is when the fan is soldered onto the PCBA. You should make sure the solder iron is grounded as well as ground the ends of the fan assembly before soldering.

The second is after soldering if someone were to touch the soldered connection. In this case it is always best to have anyone handling the assembly to be grounded by something like a wrist strap or a footwear/flooring system. If this is not feasible, the assembly should be packaged in something that is conductive or dissipative and provides shielding.

To determine the actual risk to the sensitive components is not easy to determine since they are already installed on the PCB. The component CDM and HBM numbers apply when it is not installed on the PCB. Once installed the sensitivity could be better or worse depending on a lot of factors (for example, ESD clamps built into the PCBA design, other paths on the PCB, capacitance of the PCBA, etc.). It is always best to take ESD safety precautions when handling these assemblies.

Hello,

Greetings of the day from India.

What I understand is that you will be touching open end of the wires only for final testing and the assembly is fully in sealed enclosure.

As Mr. Andy has mentioned “It is always best to take ESD safety precautions when handling these assemblies.”

While testing too , through cable discharge an ESD event can occur. Thus; until the final testing and packing of the total unit is not over it is advised to take care of ESD safety steps with bare minimum things at least ( A grounded ESD safe work surface , wrist strap worn by the operator and , ESD safe hand tools plus a table top ionizer also if any Process essential insulators are in use on the work surface.)

Thank you